Call Us 281-940-KELM

Industrial Sound and Noise Measurement

Kelm Engineering

Are you tired of listening to your neighbor’s noise? Maybe you’re the one with the noise problem, desperately searching for a solution? Either way, the first step to addressing industrial noise for sources is to document sound levels as well as the frequency content. In order to do that, you will need someone to record the sound with a sound level meter and document the results in a way that the results are accurate and defendable. Our expert team here at Kelm Engineering is here to help.

Any time that a noise complaint is made, the conditions existing at the time of the complaint are important. Sound levels can change tremendously due to common causes such as changes in the intensity or frequencies of the sound source, changes in the transmission path from the source to the observer, or weather. As a result, the changes observed over time can be hard to explain and very difficult to defend since a single measurement will likely not represent the sound at the time of the complaint.

Many times, the alleged source will be an industrial plant. This is a common complaint after a new plant or equipment is installed near a residential area or other populated locations. Rotating equipment can cause specific tones that can be annoying even at relatively low levels such as fans, motors, turbines, or alarms. Other causes can be more broadband including flare stacks, relief devices, or other flow related sources that can occur with varying intensity under different operating conditions. Documenting the actual sound levels can be difficult without some form of continuous monitoring.

Many times, the alleged source will be an industrial plant. This is a common complaint after a new plant or equipment is installed near a residential area or other populated locations. Rotating equipment can cause specific tones that can be annoying even at relatively low levels such as fans, motors, turbines, or alarms. Other causes can be more broadband including flare stacks, relief devices, or other flow related sources that can occur with varying intensity under different operating conditions. Documenting the actual sound levels can be difficult without some form of continuous monitoring.

Another complication is that the sound is observed normally at a distance from the source such as in a residential neighborhood or other occupied location. When this happens, the path that the sound travels from the source as well as the environmental conditions (wind, temperature, humidity level, etc.) have a profound impact on the sound intensity at the observer. In addition, the ambient sound can also make the sounds present seem to change in amplitude due to the nature of the ambient sounds (or lack of sound on a still night).

Measurement Methods

Sound measurements can be done at a specific location and point in time using a typical sound level meter. A sound level meter is a hand-held device that measures sound amplitude using decibels in “A” weighted units (dBA) for comparison to allowable sound levels as prescribed by local ordinances, OSHA or other sources. Some sound level meters can also provide frequency content.

Sound measurements can be done at a specific location and point in time using a typical sound level meter. A sound level meter is a hand-held device that measures sound amplitude using decibels in “A” weighted units (dBA) for comparison to allowable sound levels as prescribed by local ordinances, OSHA or other sources. Some sound level meters can also provide frequency content.

In some cases, the sounds observed may comply with required overall amplitudes, but still be considered excessive “noise” due to the detail characteristics of the sound including certain tones or frequencies present in the sound, or the characteristics of the sound changing over time. When this occurs, the sound is perceived to be a non-trivial annoyance, but may technically satisfy legal limits.

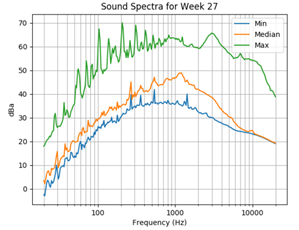

Since there are often large variations in the sound levels and frequency content, it is also imperative to record the sound characteristics over time to determine the variation in sound amplitudes, to document the peak levels, and to document the frequencies involved. This can only be done by installing a semi-permanent sound measurement system at a representative location for proper documentation.

Our Approach

We have the capability to measure sound levels using typical portable hand-held devices for the purpose of spot checking for frequencies and amplitudes at the observer’s location (in the residential area) as well as using near field measurements to evaluate the equipment at the industrial site to identify the possible sources for measured tones. This is a very good approach for an initial screening and to document sound levels at plant or residential boundaries for a specific point in time. These measurements can also be used to identify methods to reduce sound levels with appropriate engineering controls.

We have the capability to measure sound levels using typical portable hand-held devices for the purpose of spot checking for frequencies and amplitudes at the observer’s location (in the residential area) as well as using near field measurements to evaluate the equipment at the industrial site to identify the possible sources for measured tones. This is a very good approach for an initial screening and to document sound levels at plant or residential boundaries for a specific point in time. These measurements can also be used to identify methods to reduce sound levels with appropriate engineering controls.

Once the general sound characteristics are known, it is normally preferred to conduct long term sound measurements to document the impact of time, operating conditions and weather. It is also typical to also record weather conditions at the measurement site with a local weather station. The installation shown here demonstrates a typical installation with the microphone on a 6 meter-tall pole, the control box, as well as the weather station.

When the extended monitoring is conducted to record sound variations over time, the data is transferred to the cloud through secure data methods to allow remote analysis and review of the sound data.

The recorded sound data can then be used to identify likely sources and to evaluate the changes in sound levels over time. In particular, there is often certain sound frequencies that can become very loud for different operating conditions or environmental conditions as a result of the layout of the equipment or the surrounding structures.

Data below shows that there are specific tones that occur at different times as well as some broad band energy that can result from things such as flare noise. Without the extended monitoring it is very difficult to explain the causes and nature of the observed sounds.

Summary

Our team at Kelm Engineering, LLC are experts in sound monitoring. We would be happy to assist you in documenting sound on your plant site or surrounding area. Armed with the latest hardware and measurement tools, as well as our highly qualified team, we can properly analyze and easily present results. If you are tired of noise complaints, whether caused by you or your neighbors, give us a call today. We look forward to working with you soon.